ARMS - Advanced Resource Management System.

Tracks & Manages Industry’s activities from Gate Entry to Dispatch.

ARMS-Advanced Resource Management System, is a complete Resource Management System, ARMS consists of Business application that tracks & manages Industry’s Activities from Gate Entry to Dispatch. ARMS Software Helps cut expenses by getting timely information easily available for analysis and decision making.

ARMS-ERP Solutions is simple to understand and easy to use. It gives variety of module integration which can serve best in any manufacturing firm

AMGSTAR ERP KEY FEATURES

- Web Based MultiUser Software

- User level authority system

- Developed on latest technology platform

- Support Barcode printing & scanning for Inventory Management

- Compatibility with Word, Excel & PDF download

- Supports auto Email to Customer & suppliers

- Improves productivity by avoiding repetitive tasks.

- Graphical Analysis with Interactive Dashboards.

- Customization available as per business needs.

- Reporting part on Mobile app as per requirement

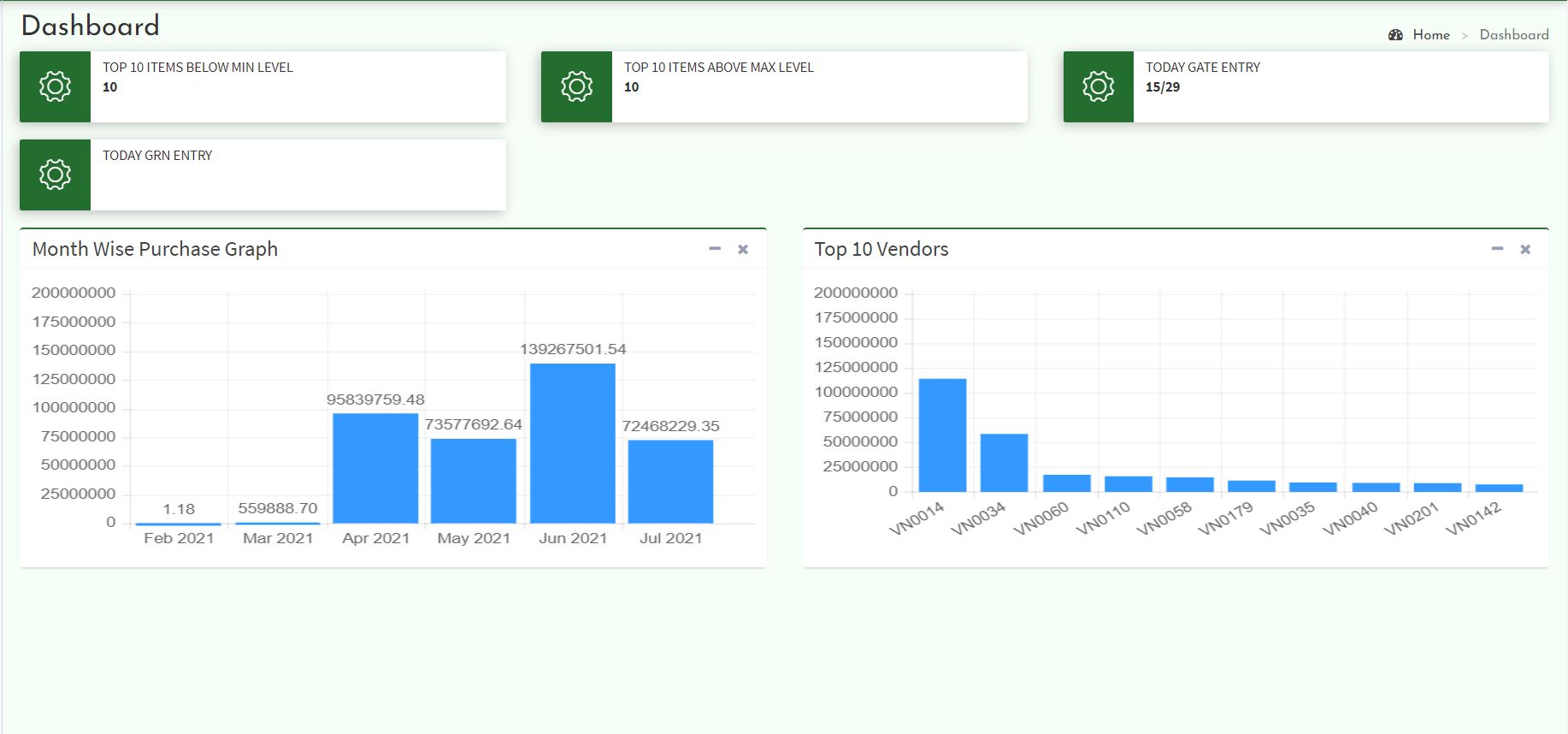

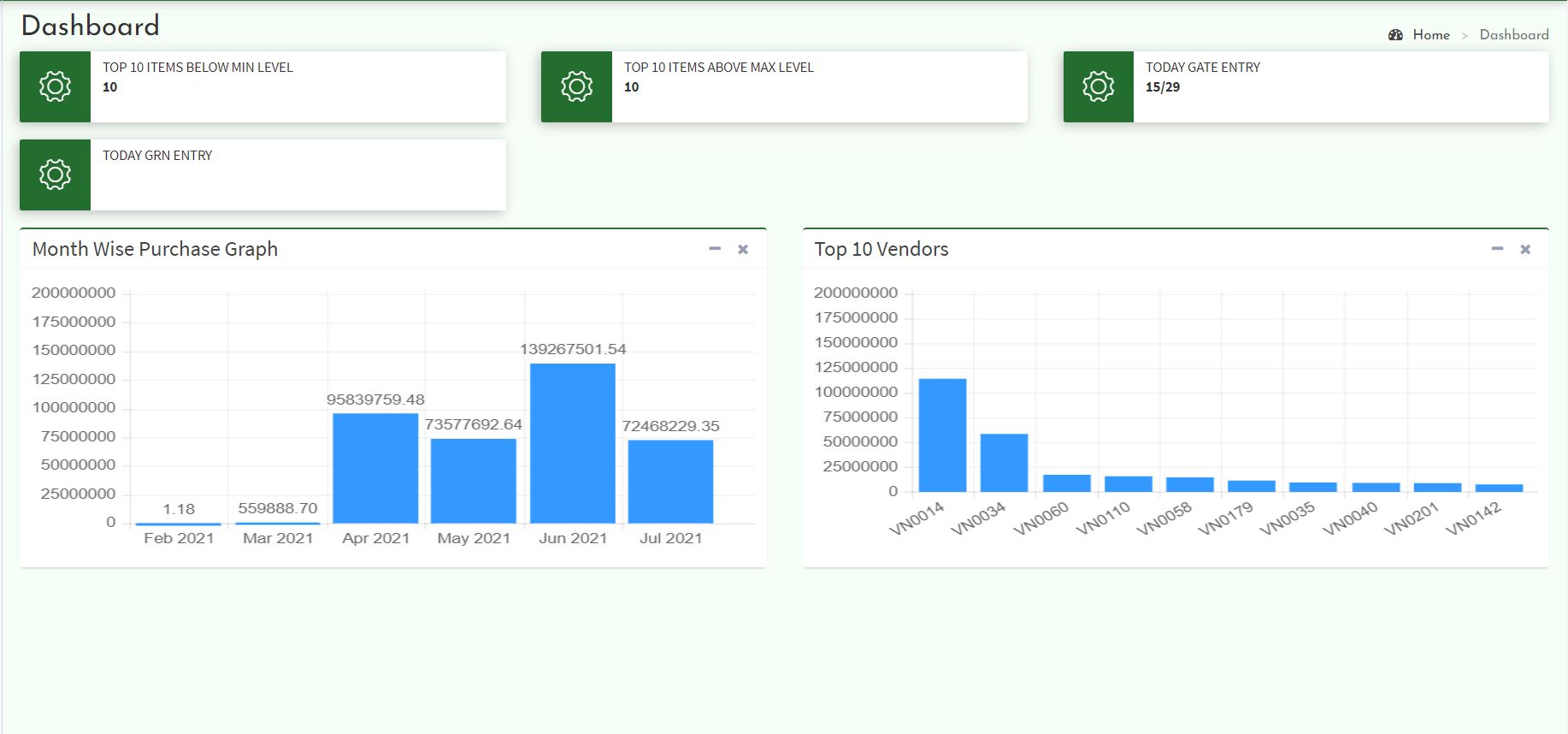

PURCHASE MANAGEMENT

Purchase Management has a vital role to play, in a manufacturing organization. It procures the items/material required by an organization and thus fulfills the necessary item requirements of various departments. In case of shortage in stock or at reorder level, it deals with multiple suppliers in an endeavor to procure new stock and also makes sure that the material is procured in the best possible quality, cost & time. The basic purpose of ERP Purchase Module is to streamline the functioning of procurement/purchase of inventory (raw-material), assign orders to suppliers and bill.

INVENTORY MANAGEMENT

Store is an essential part of any manufacturing organization. The objective of a store is to smoothly and economically provide the right materials at the right time, and in the right condition. Keeping a close eye on the level of inventory requirements is the key to smooth and uninterrupted functioning of any production department. Our INVENTORY MANAGEMENT module helps you meet your supply chain goals by achieving perfect order fulfillment and reduced operational (holding) cost. By generating detailed reports on various essential aspects of store management, it offers visibility into critical inventory levels.

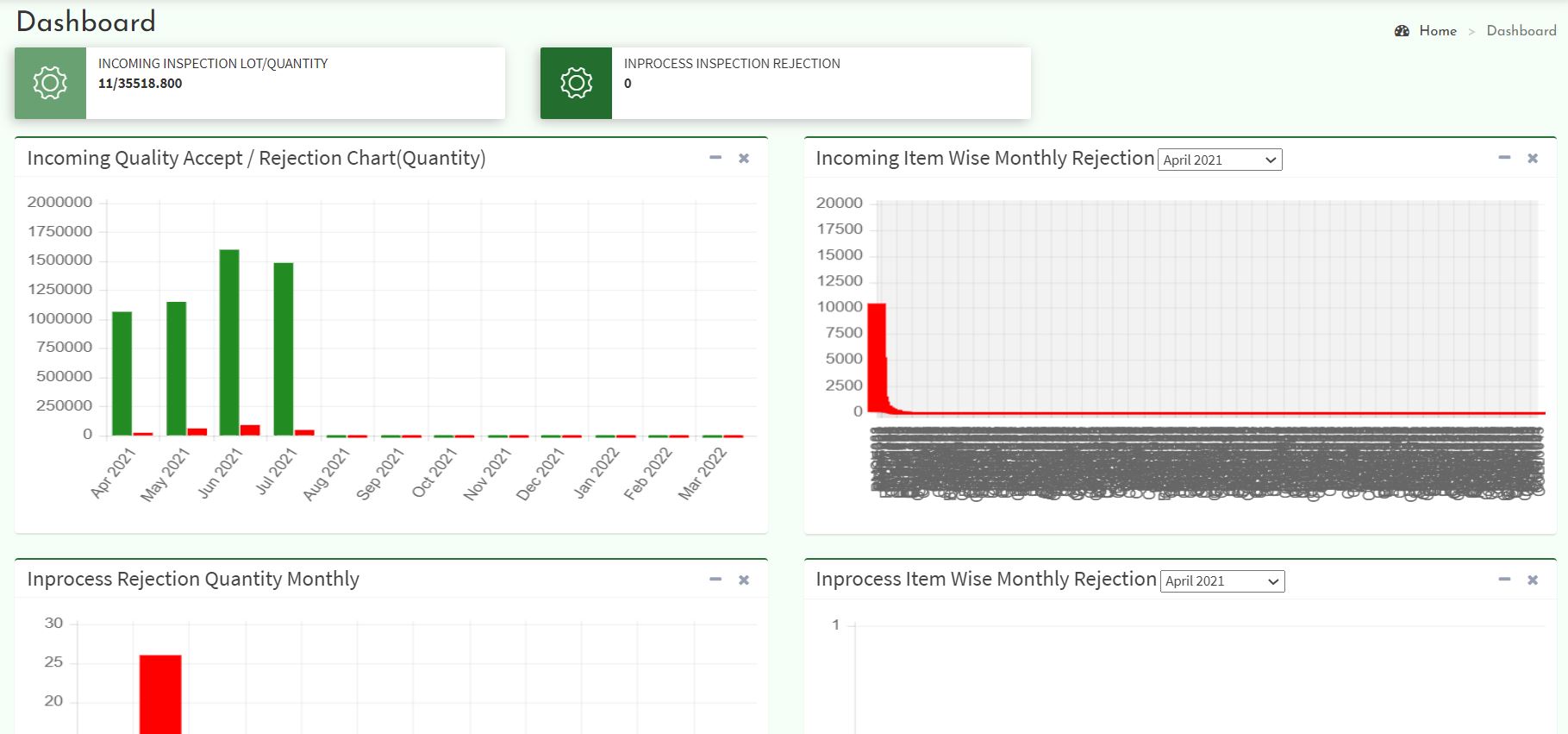

QUALITY MANAGEMENT

This Module not only monitors quality by control plans in purchasing and manufacturing but also provides real-time process capability index for quick review. It provides support for every phase of your operations, from receipt and acceptance of raw materials, through production of intermediates, to inspections of finished goods before shipment to Customers..

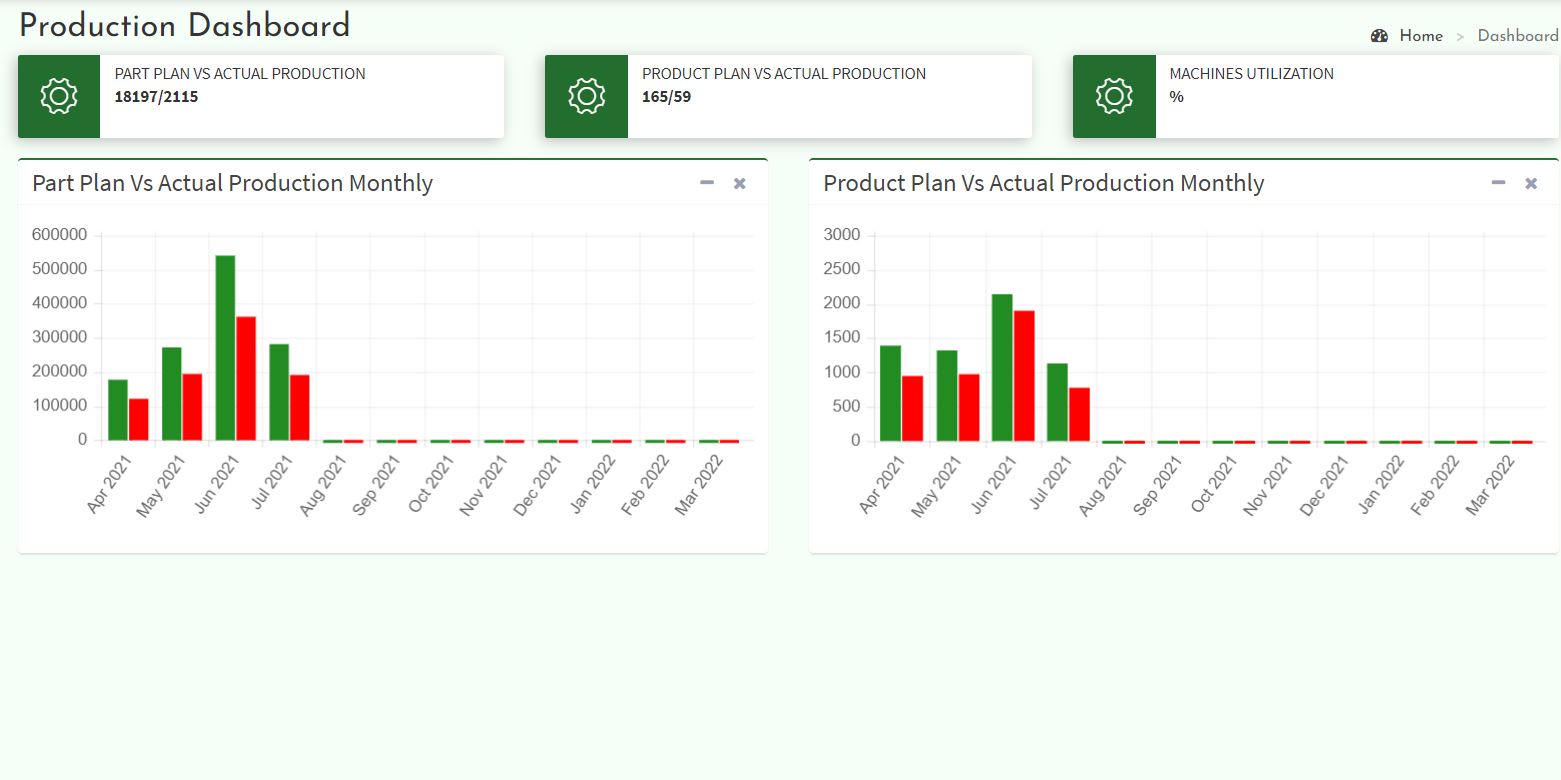

PLANNING & PRODUCTION MANAGEMENT

Production Management is the process of managing products throughout the life cycle. A key Objective for Production Management is Planning and Developing the Specifications for a range of Products or a Product Portfolio that meets a long-term Strategic Plan. It focuses to produce Goods & Services as per the Estimated Manufacturing, to produce Right Quality of Goods & Services as per the Established Standards and as per decided time schedule. It also aims at maximizing the utilization of Manpower and minimizing the use of Resources to the Optimum Level. Production Management includes the process of making BOM (Bill of Material), Store Requisition from Stage, Store Issue, Production & Movement and Quality Inspection. In short, anything you can expect from a complete Production ERP, is here.

MACHINE MAINTENANCE

Machine maintenance is the work that keeps mechanical assets running with minimal downtime. Machine maintenance can include regularly scheduled service, routine checks, and both scheduled and emergency repairs...